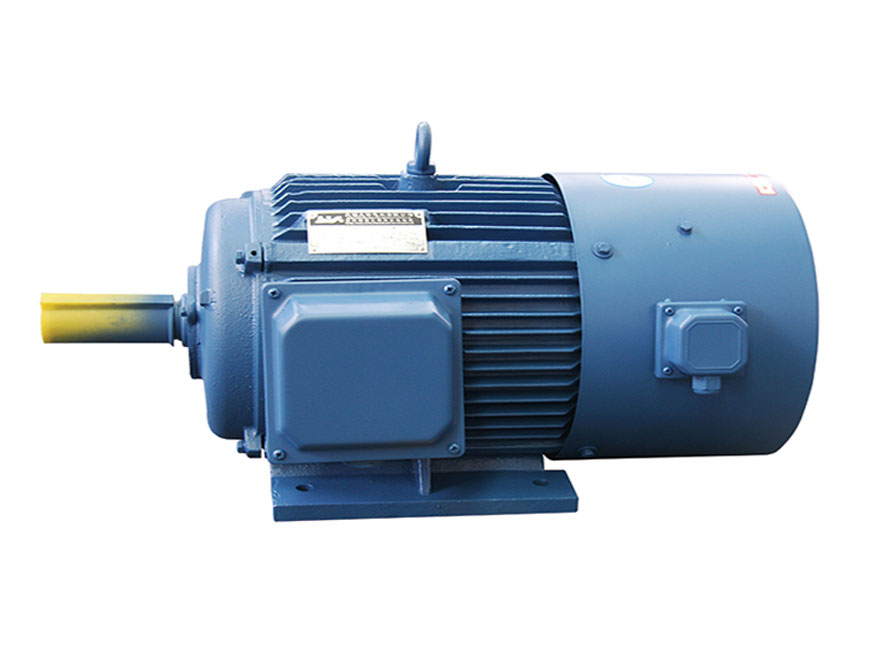

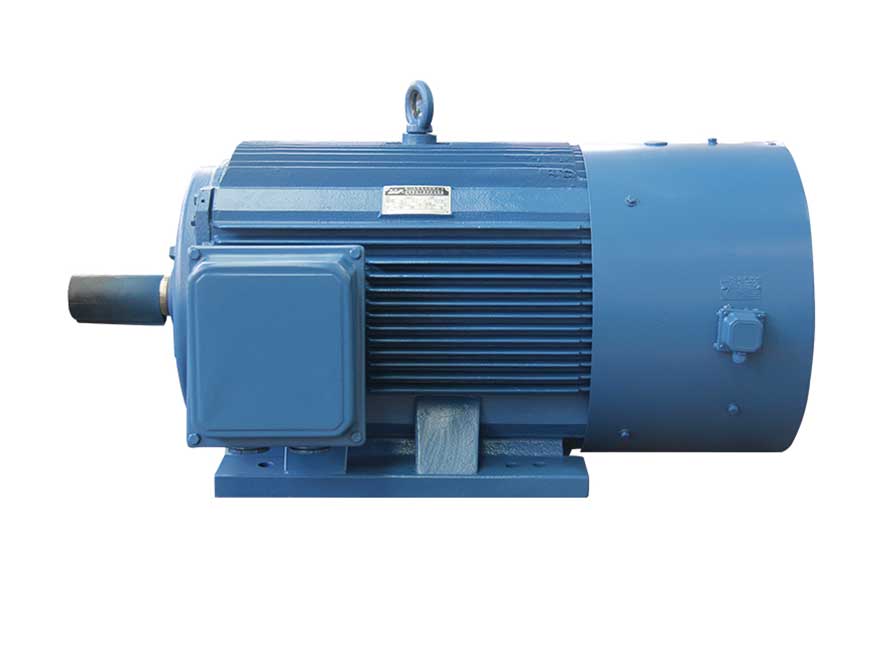

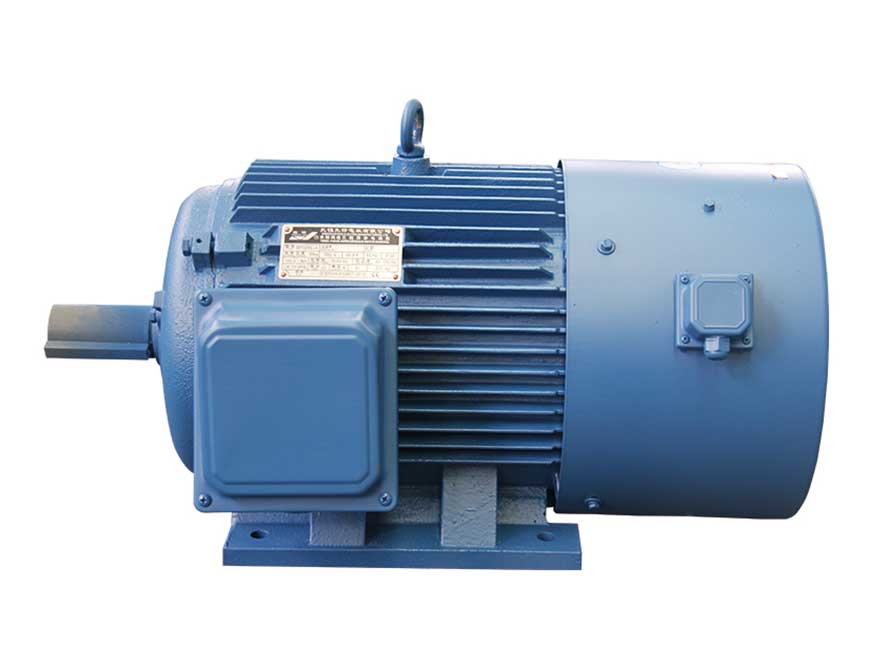

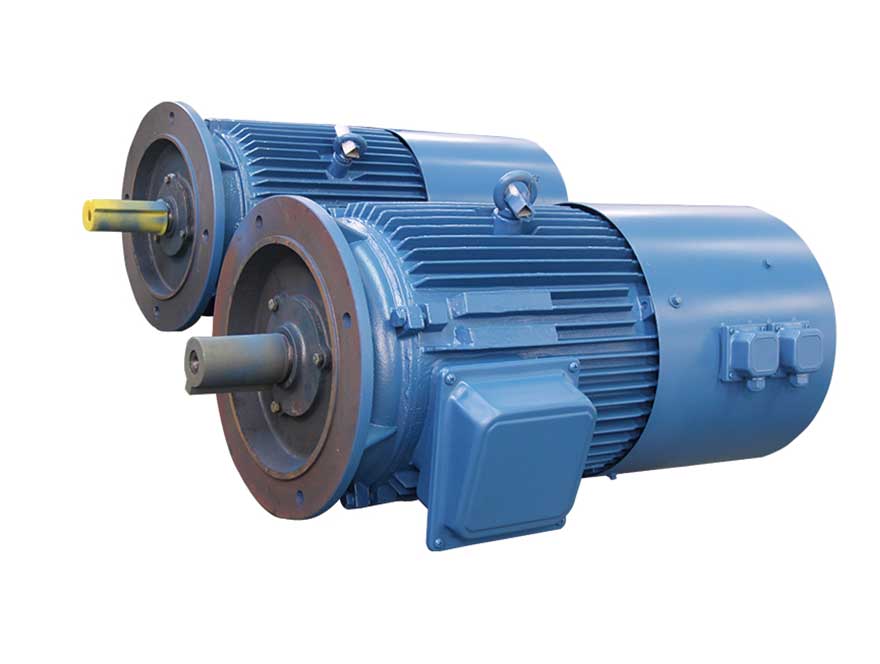

General Description

YVF2 (BPY) series three phase AC frequency conversion &speed-regulating asynchronous motor is the latest product successfully developed on the basis of absorbing the foreign product technology, widely researching and collecting relevant domestic and overseas information. It has the advantages of low noises, low vibrations, wide speed adjustable range, reliable running and easy maintenance. It can be used to support various frequency conversion devices at home and abroad. And it is helpful to energy saving and automatic control.

YVF2 (BPY) series three phase AC frequency conversion &speed-regulating asynchronous motor is designed with the VVVF frequency conversion &speed-regulating motor computer aided design program and CAD technology. When the motor runs at low speed (5-50Hz), it has high starting torque, and it can run at constant torque within the scope of 1:10. And the running is stable without torque crawling phenomenon. When the motor runs at high speed (50-100Hz), it has high overload ability to ensure the constant power output of the motor. The motor is force ventilated with separate axial flow fan to ensure the good cooling results of the motor when running at different rotating speed. This motor has reliable insulation and good performance. We adopt advanced dielectric analysis method to manage the quality of the main insulation materials, such as electromagnetic wire and impregnating varnish. During the insulating treatment process, we adopt dynamic dielectric measurement to control the impregnating varnish baking process and ensure the reliable insulation quality of the motor. It also has good adaptability to the over-voltage caused by the high carrier frequency of the converter. Meanwhile we can set computer control interfaces according to the customer requirements. It has contribute to achieving the automatic control of the speed-regulating system. You can also assemble a brake at the non shaft extension end to facilitate rapid brake.

YVF2 (BPY) series three phase AC frequency conversion &speed-regulating asynchronous motor can be widely used in the constant torque (5-50Hz) and constant power (50-100Hz) speed-regulating of machine tools, textile, chemical, metallurgy, industrial washing machine industries as well as the energy saving and speed-regulating of fan and water pump. It can meet the requirements of the drive field in paper making, plastic, packing, lift, crane and other special industries.

Ⅰ Conditions of Usage

1. Altitude above sea level shall not exceed 1000m.

2. The ambient temperature is no more than 40℃.

3. The motor protective grade is IP44.

4. Relative humidity: no more than 90% (when below 20℃)

5. Working form: S1 continuous

6. Insulation grade: B (or F)

7. The motor rated voltage is 380V, frequency 50Hz. We can also determine the rated point of voltage and frequency according to customer requirements.

Ⅱ Main Technical Performances and Data

For powers which line frequency is 50Hz (or 60Hz), its speed-regulating range is often 5Hz-100Hz (or 6Hz-120Hz) (1:20). The motor will output rated torque at 5Hz-50Hz (or 6Hz-60Hz), and it is the constant torque running zone. At 50Hz-100Hz (60Hz-120Hz), the motor will output rated power, and it is the constant power running zone.

When the frequency conversion power supplying is at low frequency, the rate of starting torque and rated torque can reach 1.25. For technical data, you can refer to Table 1.

Norminal Power

(KW) | 2Poles | 4 Poles | 6 Poles | 8 Poles | 10 Poles |

Model No

(H) | Rated Current (A ) | Rated Torque

(N.m) | Model No

(H) | Rated Current (A ) | Rated Torque

(N.m) | Model No

(H) | Rated Current (A ) | Rated Torque

(N.m) | Model No

(H) | Rated Current (A ) | Rated Torque

(N.m) | Model No

(H) | Rated Current (A ) | Rated Torque

(N.m) |

| 0.55 |

|

|

| 80M1 | 1.6 | 3.5 |

|

|

|

|

|

|

|

|

|

| 0.75 | 80M1 | 1.9 | 2.4 | 80M2 | 2.1 | 4.7 | 90S | 2.3 | 7.1 |

|

|

|

|

|

|

| 1.1 | 80M2 | 2.6 | 3.5 | 90S | 2.7 | 7.0 | 90L | 3.2 | 10.5 |

|

|

|

|

|

|

| 1.5 | 90S | .34 | 4.7 | 90L | 3.7 | 9.5 | 100L | 4 | 14.3 |

|

|

|

|

|

|

| 2.2 | 90L | 4.7 | 7 | 100L1 | 5.0 | 14.0 | 112M | 5.6 | 21.0 | 132S | 5.8 | 28.0 |

|

|

|

| 3. | 100L | 6.4 | 9.5 | 100L2 | 6.8 | 19.1 | 132S | 7.2 | 28.6 | 132M | 7.7 | 38.2 |

|

|

|

| 4 | 112M | 8.2 | 12.7 | 112M | 8.8 | 25.4 | 132M1 | 9.4 | 38.2 | 160M1 | 9.9 | 50.9 |

|

|

|

| 5.5 | 132S1 | 11.1 | 17.5 | 132S | 11.6 | 35 | 132M2 | 12.6 | 52.5 | 160M2 | 13.3 | 70.0 |

|

|

|

| 7.5 | 132S2 | 15 | 23.8 | 132M | 15.4 | 47.7 | 160M | 17 | 71.6 | 160L | 17.7 | 95.5 |

|

|

|

| 11 | 160M1 | 21.8 | 35 | 160M | 22.6 | 70.0 | 160L | 24.6 | 105.0 | 180L | 25.1 | 140.1 |

|

|

|

| 15 | 160M2 | 29.4 | 47.7 | 160L | 30.3 | 95.5 | 180L | 31.4 | 143.3 | 200L | 34.1 | 191.1 |

|

|

|

| 18.5 | 160L | 35.5 | 58.9 | 180M | 35.9 | 117.8 | 200L1 | 38.1 | 176.7 | 225S | 41.3 | 235.6 |

|

|

|

| 22 |

|

|

| 180L | 42.5 | 140.1 | 200L2 | 44.7 | 210.0 | 225M | 47.6 | 280.1 |

|

|

|

| 30 |

|

|

| 200L | 56.8 | 190.9 | 225M | 58 | 286.0 | 250M | 63 | 382.0 |

|

|

|

| 37 |

|

|

| 225S | 70.4 | 235.5 | 250M | 72 | 353.0 | 280S | 77.2 | 471.1 |

|

|

|

| 45 |

|

|

| 225M | 84.2 | 256.4 | 280S | 85.9 | 429.0 | 280M | 94.1 | 573.0 | 315S | 99.1 | 716.3 |

| 55 |

|

|

| 250M | 102.5 | 350.1 | 280M | 104.7 | 525.0 | 315S | 111.2 | 700.3 | 315M | 121.1 | 875.4 |

| 75 |

|

|

| 280S | 139.6 | 477.4 | 315S | 141.7 | 716.3 | 315M | 151.3 | 955.0 | 315L1 | 162.1 | 1193.8 |

| 90 |

|

|

| 280M | 166.8 | 572.9 | 315M | 169.5 | 859.5 | 315L1 | 177.8 | 1146.0 | 315L2 | 190.9 | 1432.5 |

| 110 |

|

|

| 315S | 198.7 | 700.2 | 315L1 | 206.7 | 1050.5 | 315L2 | 216.8 | 1400.7 | 355M1 | 230 | 1736 |

| 132 |

|

|

| 315M | 237.7 | 840.3 | 315L2 | 244.7 | 1260.6 | 355M1 | 265 | 1680.8 | 355M2 | 275 | 2083 |

| 160 |

|

|

| 315L1 | 284.3 | 1018.5 | 355M1 | 282.3 | 1528 | 355M2 | 313.4 | 2037.3 | 355L | 333 | 2546.5 |

| 200 |

|

|

| 315L2 | 354.6 | 1273.2 | 355M2 | 364.6 | 1910 | 355L | 386.2 | 2546.7 |

|

|

|

| 250 |

|

|

| 355M | 441.9 | 1591.7 | 355L | 454.3 | 2387.5 |

|

|

|

|

|

|

| 315 |

|

|

| 355L | 494.9 | 2005.5 |

|

|

|

|

|

|

|

|

|

Ⅲ Installation Form

Ⅳ Matched Cooling Fan

ⅤInstallation Size and Dimensions

No Footing, end cover with flanges(IMB5, IMV1,IMV3)

With footing, end cover no flanges(IMB3, IMB6, IMB7, IMB8,IMV5,IMV6)

With footing, end cover with flanges(IMB35, IMB6, IMV15,IMV36)

Note: 1. The 80 and 90 motor bases have no lifting hook.

2. R is the distance between flange installation surface to shaft extension step surface.

| Model No. | Installation size mm |

| H | A | B | C | D | E | FXGD | G | K | T | M | N | P | R | S |

| 2Poles | 2

Poles | 4.6.8

Poles

| 2

Poles | 4.6.8

10 Poles

| 2

Poles | 4.6.8

10 Poles

|

| 80 | 80 | 125 | 100 | 50 | 19 | 40 | 6×6 | 15.5 | 10 | 3.5 | 165 | 130 | 200 |

| 4-φ12 |

| 90S | 90 | 140 | 56 | 24 | 50 | 8×7 | 20 | 0 |

| 90L | 125 |

| 100L | 100 | 160 | 140 | 63 | 28 | 24 | 12 | 4 | 215 | 180 | 250 | 4-φ15 |

| 112M | 112 | 190 | 70 | 60 |

| 132S | 132 | 216 | 89 | 38 | 80 | 10×8 | 33 | 265 | 320 | 300 |

| 132M | 178 |

| 160M | 160 | 254 | 210 | 108 | 42 | 110 | 12×8 | 37 | 15 | 5 | 300 | 250 | 350 | 4-φ19 |

| 160L | 254 |

| 180M | 180 | 279 | 241 | 121 | 48 | 14×9 | 42.5 |

| 180L | 279 |

| 200L | 200 | 318 | 305 | 133 | 55 | 16×10 | 49 | 19 | 350 | 300 | 400 |

| 225S | 225 | 356 | 286 | 149 | 110 | 140 | 16×10 | 18×11 | 49 | 53 | 400 | 350 | 450 | 8-φ19 |

| 225M | 311 | 55 | 60 | 53 |

| 250M | 250 | 406 | 349 | 168 | 60 | 65 | 140 | 18×11 | 58 | 58 | 24 | 500 | 450 | 550 |

| 280S | 280 | 457 | 368 | 190 | 65 | 75 | 18×11 | 20×14 | 67.5 |

| 280M | 419 |

| 315S | 315 | 508 | 406 | 216 | 80 | 140 | 170 | 20×14 | 71 | 28 | 6 | 600 | 550 | 660 | 8-φ24 |

| 315M | 457 |

| 315L | 508 |

| 355M | 355 | 610 | 560 | 254 | 75 | 95 | 20×12 | 25×14 | 67.5 | 86 | 740 | 680 | 800 |

| 355L | 630 |